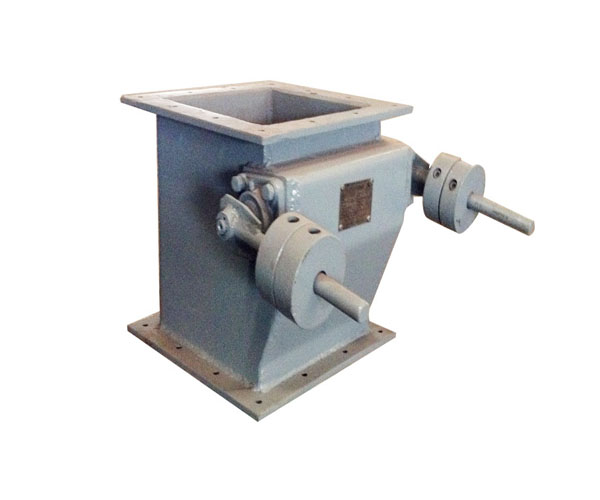

鎖氣翻闆(pan)卸灰閥普(pǔ)遍适用于(yú)建材、冶金(jin)、石化、電力(li)、礦🌏山、輕👄工(gong)等行業,作(zuo)為各類除(chú)塵設備的(de)灰鬥鎖氣(qì)卸灰裝置(zhi),及各種磨(mo)機、烘幹機(jī)、料倉、筒庫(kù)和閉式輸(shu)送系統等(deng)的鎖🏃氣、卸(xiè)灰裝置。

This valve is widely used in the building material, metallurgy, oil chemical, electric power, mining and light industries etc. It is the discharging or air-locking device of all kinds of removing dust equipment and grinding machine, drying machine, storing house and closing carrying system.

結(jié)構特點:

Structure characteristic:

鎖(suo)氣翻闆卸(xie)灰閥為上(shàng)下交替開(kāi)閉,自動複(fú)位機構。分(fèn)為:Z為重錘(chuí)🔱自動複位(wèi)機構,具有(yǒu)運轉平穩(wen)、節能,卸灰(huī)量大、小可(kě)調🌈,卸灰、鎖(suo)氣可靠之(zhi)功能。C為吊(diào)錘自動複(fu)位機構,具(jù)有占地面(mian)積省、節能(néng),卸灰調節(jie)方便,卸灰(huī)、鎖氣可靠(kào)之功能。B為(wei)凸輪、連杆(gǎn)傳動,重量(liang)自動複位(wèi)機構;D為凸(tū)😘輪、連杆傳(chuan)動,彈簧自(zì)動複位機(jī)構,具有結(jié)構緊湊、設(she)計合理、運(yun)轉平穩,卸(xiè)灰、鎖氣可(ke)靠。是各種(zhong)無粘度🥵的(de)固體粉料(liào),小于Φ10mm的顆(ke)粒料,晶體(tǐ)料,團狀料(liao)♍,給、卸料工(gōng)況的理想(xiang)設備。Ⅰ型為(wéi)單闆卸料(liao),Ⅱ型為雙闆(pǎn)卸料。

The valve is the automatic replacement machine of opening and closing alternately. There are four types of valve: type Z is heavy hammer automatic replacement machine, having the features of calm operation, saving energy, adjustable discharging and reliable discharging and air-locking etc. type C is the suspending hammer automatic replacement machine, having the features of saving energy, little in area, convenient in discharging adjust and reliable discharging and air locking etc. Type B is the gravity automatic replacement machine with transmission of cam and connecting pole. Type D is the spring automatic replacement machine with transmission of cam and connecting pole, having the features of compact structure, reasonable design, calm operation and reliable discharging and air locking. It is the ideal equipment of all kinds of non-glutinosity, grain less than Φ10mm , crystalloid, block material and supply or discharge of material working conditions. Type Ⅰ is the single disc discharging and type Ⅱ is the double disc discharging.

性能(néng)參數:

Performance parameter:

适用介質(zhì) Suitable medium | 适用(yong)溫度 Suitable temperature | 卸灰能力(li) Discharge amount |

幹燥(zao)粉塵、顆粒(li)、晶體料等(deng) Dry powder dust, grain, crystalloid etc | 150℃ | 3~168m3/h |

ESX系列 外形(xíng)連接尺寸(cùn):

Appearance joint dimension:

A×A1 | B×B1 | C×C1 | H1 | H2 | L1 | L2 | L3 | n-d | 傳動裝置(zhì) Driving device | 功率(lǜ) KW |

150×150 | 195×195 | 230×230 | 500 | 420 | 705 | 8-Φ10 | BWY-15-59 | 0.6 | ||

200×200 | 245×245 | 280×280 | 600 | 490 | 782 | 8-Φ10 | BWY-15-59 | 0.6 | ||

220×220 | 265×265 | 300×300 | 600 | 510 | 802 | 8-Φ10 | BWY-15-59 | 0.6 | ||

250×250 | 305×305 | 350×350 | 600 | 580 | 867 | 12-Φ10 | BWY-18-71 | 0.8 | ||

300×300 | 355×355 | 400×400 | 750 | 600 | 610 | 1220 | 1240 | 12-Φ10 | BWY-22-71 | 1.1 |

320×320 | 375×375 | 420×420 | 750 | 600 | 630 | 1260 | 1264 | 12-Φ12 | BWY-22-71 | 1.1 |

400×400 | 455×455 | 500×500 | 850 | 700 | 750 | 1500 | 1550 | 16-Φ12 | BWY-2215-121 | 1.5 |

428×428 | 483×483 | 528×528 | 850 | 700 | 764 | 1528 | 1600 | 16-Φ12 | BWY-2215-121 | 1.5 |

450×450 | 505×505 | 550×550 | 850 | 700 | 775 | 1550 | 1680 | 16-Φ12 | BWY-2215-121 | 1.5 |

480×480 | 535×535 | 580×580 | 850 | 700 | 790 | 1580 | 1720 | 20-Φ14 | BWY-2215-121 | 1.5 |

500×500 | 555×555 | 600×600 | 850 | 800 | 800 | 1600 | 1750 | 20-Φ14 | BWY-2215-121 | 1.5 |

600×600 | 655×655 | 700×700 | 850 | 850 | 960 | 1920 | 1820 | 20-Φ14 | BWY-2715-121 | 3.18 |

480×690 | 535×745 | 580×790 | 850 | 800 | 790 | 1580 | 1910 | 20-Φ14 | BWY-2715-121 | 3.18 |

400×720 | 455×775 | 500×820 | 900 | 800 | 750 | 1500 | 2210 | 18-Φ14 | BWY-2715-121 | 3.18 |

600×800 | 655×855 | 700×900 | 900 | 850 | 960 | 1920 | 2290 | 22-Φ14 | BWY-2715-121 | 3.18 |

800×800 | 855×855 | 900×900 | 1300 | 1200 | 1060 | 2320 | 2290 | 24-Φ14 | BWY-2715-121 | 3.18 |

800×1000 | 855×1070 | 900×1130 | 1200 | 2320 | 2400 | 28-Φ18 | BWY-2715-121 | 3.18 | ||

1000×1000 | 1070×1070 | 1130×1130 | 1300 | 2940 | 2400 | 28-Φ18 | BWY-3322-187 |

湖北大庆(qing)万美塑料(liào)制造有限(xiàn)公司 版權(quan)所有 荊州(zhou)百捷 技術(shu)支持

地址(zhǐ):荊州市沙(shā)市區十号(hào)路 咨詢熱(rè)線:0716-8878286

·

•