湖北大庆万美塑(su)料制造有限公司(sī),歡迎您! 今天是:

This valve is widely used in the pipe system transporting coal gas, natural gas, venting and environment protection in building material, glass, mining, power, light industry and papermaking departments. The technique is introduced from foreign Company. It can change the flow and cut off gas medium in the pipe by the different control signal.

Structure characteristic:

The valve has the features of compact structure, endurance, little in the lost of flow resistance, good seal, reliable self-locking, flexible operation, definite direction, easy to maintenance and long life. The seal of driving shaft is out seal, which is easy to be adjusted and changed without stopping, so the out leakage is avoided effectively. All kinds of seal type can suit different medium. It is especially suitable in the condition of adjusting, cutting off and self-protecting quickly. The valve is used with worm gear driving and electric device to form a complete set to realize open-close operation. It is the ideal equipment of adjusting flow.

性(xìng)能參數:

Nominal pressure (MPa) | 0.05 | |

密封試(shi)驗壓力Seal test pressure(MPa) | 0.055 | |

強度(du)試驗壓力Strength test pressure(MPa) | 0.075 | |

适(shì)用溫度Suitable temperature | -10℃℃軟密封 | -10℃ -350℃硬密封Hard sealing |

使用(yòng)介質Suitable medium | 空氣、煙(yan)氣、粉塵氣體等 Air, smoke, gas with powder etc | |

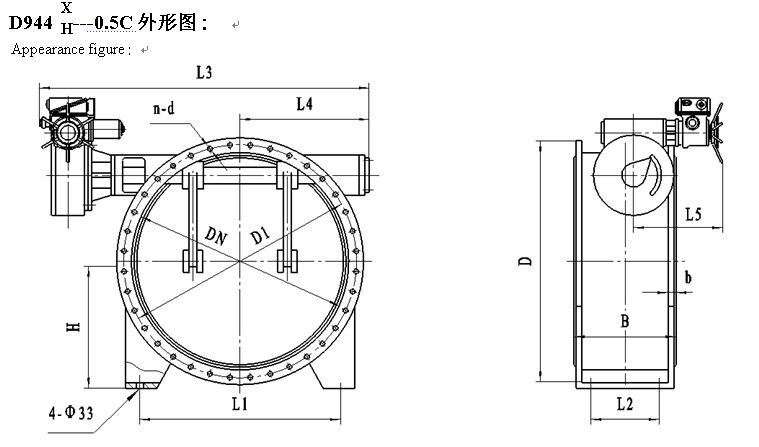

D944 X H---0.5C外(wai)形連接尺寸:

Appearance joint dimensions:

DN | D | D1 | B | b | n-d | H | L1 | L2 | L3 | L4 | 電動裝置 Electric device | ||

400 | 455 | 400 | 10 | Φ14 | 816 | 500 | Z10-36 P:0.37KW | ||||||

450 | 550 | 400 | 16-Φ14 | 870 | 325 | 500 | |||||||

555 | 450 | 10 | 20-Φ14 | 920 | 350 | 500 | Z20-36 | 135 | |||||

600 | 700 | 655 | 10 | 408 | 155 | ||||||||

700 | 800 | 755 | 500 | 460 | 550 | Z30-36 P:1.1 KW | 205 | ||||||

800 | 855 | 10 | Φ14 | 1216 | 518 | 230 | |||||||

900 | 1000 | 550 | 24-Φ14 | 1316 | 568 | 260 | |||||||

1000 | 1130 | 1070 | 12 | 28-Φ18 | 1516 | 600 | Z60-18 P:2.2 KW | 305 | |||||

1100 | 600 | 12 | 28-Φ | 600 | 340 | ||||||||

1330 | 1270 | 12 | 28-Φ18 | 1766 | 718 | 600 | 370 | ||||||

1300 | 1430 | 1370 | 650 | 32-Φ18 | 1866 | 768 | 650 | Z90-18 :3.0 KW | 420 | ||||

1530 | 1470 | 650 | 36-Φ | 1966 | 818 | 650 | 460 | ||||||

1500 | 1570 | 12 | 36-18 | 895 | 1160 | 120 | 2126 | 878 | 510 | ||||

1600 | 1730 | 1670 | 12 | 40-18 | 945 | 2176 | 928 | ZD120-18 :4.0 KW | |||||

1700 | 1770 | 750 | 16 | 40-Φ18 | 995 | 1360 | 2330 | 980 | 700 | 730 | |||

1870 | 750 | 44-Φ18 | 1045 | 1460 | 2380 | 700 | 775 | ||||||

1900 | 800 | 16 | Φ | 1560 | 2480 | 1080 | 800 | Z180-18 P:7.5 KW | 830 | ||||

2000 | 2070 | 16 | 48-Φ22 | 1145 | 1660 | 120 | 1130 | 800 | 920 | ||||

2100 | 2170 | 850 | 48-Φ22 | 1660 | 120 | 2806 | 1180 | 800 | 1000 | ||||

2200 | 2330 | 2270 | 850 | 1285 | 170 | 2866 | 800 | ||||||

2300 | 2430 | 2370 | 900 | 16 | 48-Φ22 | 1335 | 1860 | 170 | 2916 | 1288 | 900 | :7.5 KW | 1200 |

2400 | 2470 | 900 | 16 | 1385 | 1960 | 170 | 2966 | 900 | 1300 | ||||

2630 | 2570 | 950 | 16 | 22 | 170 | 3016 | 900 | 1740 | |||||

2600 | 2670 | 950 | 52-Φ22 | 2160 | 170 | 3086 | 1438 | 900 | |||||

2700 | 2830 | 1000 | 20 | 56-22 | 2200 | 210 | 1498 | 1000 | Z400-18 | 1740 | |||

2800 | 2930 | 2870 | 1000 | 60-Φ | 1615 | 2300 | 210 | 3286 | 1545 | 1000 | 2100 | ||

2900 | 1665 | 2400 | 210 | 1605 | 1000 | Z600-18 P15.0 KW | 2235 | ||||||

3000 | 3130 | 20 | 60-Φ22 | 1715 | 2500 | 3486 | 1665 | 1000 |