DOUBLE-PIPE SCREW FEEDING ENGINE

該設備采用擺(bai)線針輪減速機,加(jiā)裝VF變頻器,調速範(fan)⛷️圍廣👨❤️👨,運📱轉平穩、噪(zào)聲低、結構緊湊、體(ti)積小,可以方便地(di)調💛節物料流量,滿(man)💛足不🎯同生産工藝(yì)要求。

The device is equipped with cycloid pin wheel speed reducer and VF transducer. It has the features of great range of timing, smooth operation, low noise, compact structure and small volume. It can adjust flow of material expediently and meet the demand of different production technics.

型号說明:

SLW-×××-××××

進(jìn)出料口中心距 mm Center interval of inlet and outlet

規格代号(hao) Spec code

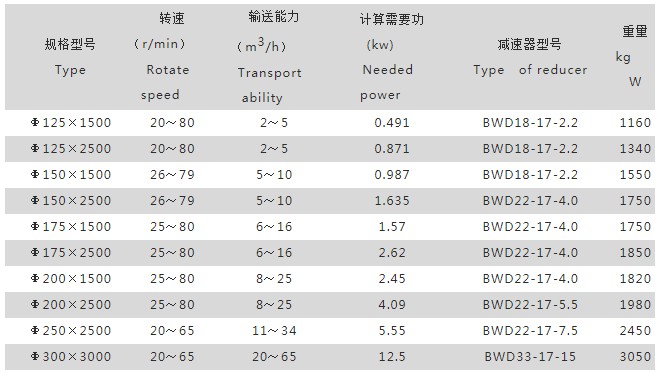

雙管螺旋喂料機(jī)主要技術參數:

喂(wèi)料能力計算:

式中(zhōng):

Q---雙管螺旋喂料機(ji)的喂料能力(m3/h)

Feeding ability

D---螺旋(xuan)葉直徑(m)

Diameter of screw leaf

d---螺旋杆直(zhí)徑(m)

Diameter of screw pole

S---螺旋的螺距(m)

Interval of screw

Thickness of screw leaf

n---螺旋的(de)轉速(r/min)

Rotate speed of screw

Filling coefficient of material

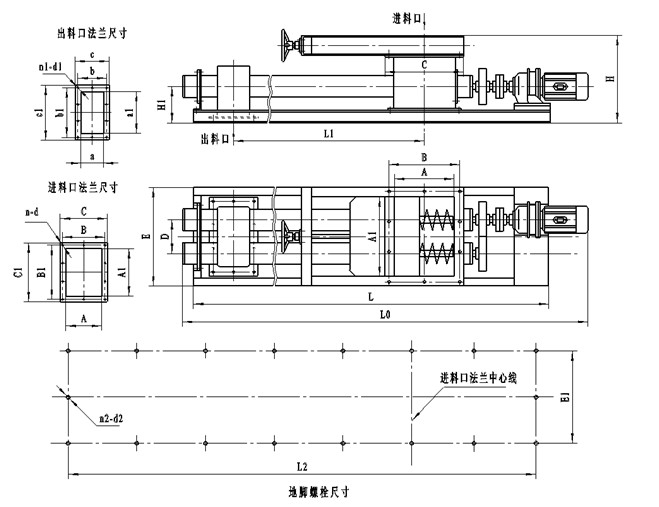

SLW外形圖(tú):

Appearance figure:

SLW外形連接尺寸:

Appearance joint dimension:

規格 | a×a1 | b×b1 | c×c1 | n1-d1 | A×A1 | B×B1 | |

Φ×1500 | 200× | 270×570 | 320620 | 20-Ф13 | 500× | 570×570 | |

200×500 | 270×570 | ×620 | 500×500 | 570×570 | |||

Φ150×1500 | 270×670 | 320×720 | Ф13 | 670670 | 720 | ||

Φ150×2500 | 670 | 320×720 | 600×600 | 670×670 | 720×720 | ||

230×700 | ×780 | 360×830 | 700×700 | ×780 | |||

230× | 310×780 | 360×830 | Ф13 | 700×700 | 780×780 | ||

Φ200×1500 | ×800 | 390×940 | 28-Ф | 800 | 940× | ||

Φ200×2500 | 330×880 | 390×940 | 28-Ф13 | 880×880 | 940940 | ||

Φ250×2500 | 250×1000 | 330×1080 | 390×1140 | Ф13 | 1080 | ||

Φ300×3000 | 250×1200 | 3301280 | 44-Ф | 1200×1200 | 1280×1280 |

SLW外形連(lián)接尺寸:

Appearance joint dimension:

n-d | n2-d2 | H | H1 | L | L0 | D | L2 | E1 | |||

Φ125×1500 | 16-18 | 643 | 268 | 2000 | 1500 | 250 | 620 | 1950 | |||

16-18 | 32-Ф22 | 643 | 4000 | 2500 | 250 | 620 | 3950 | 570 | |||

Φ150×1500 | 650 | 275 | 3000 | 3950 | 1500 | 300 | 720 | 2950 | 670 | ||

Φ1502500 | 16-Ф18 | 34-Ф22 | 650 | 275 | 4000 | 4950 | 300 | 720 | |||

175×1500 | Ф18 | 678 | 275 | 3200 | 1500 | 350 | 830 | 3150 | |||

36-22 | 678 | 4200 | 350 | 830 | 4150 | 780 | |||||

Φ200×1500 | 20-Ф18 | 305 | 3430 | 4380 | 400 | 940 | 3370 | ||||

Φ200×2500 | 20-Ф18 | 683 | 5380 | 400 | 940 | ||||||

42-Ф22 | 728 | 4850 | 570 | 4790 | 1080 | ||||||

Φ300×3000 | 32- | 48-Ф22 | 385 | 5550 | 6500 | 3000 | 1340 | 5490 |

使用說明(ming):

Usage explanation:

l 安裝時螺旋機各(ge)機殼及兩端機架(jià)的縱向不直度和(he)水平😍度允差為長(zhǎng)度的1/1000。底座在機殼(ké)裝妥以後使🧡之着(zhe)實,再🔞擰緊🌐地腳螺(luo)釘。

l 運行應平穩(wěn)可靠,軸承箱不得(de)發生漏油現象,軸(zhou)承溫升不得😘超過(guo)20℃。

l 必(bi)需保證輸送機無(wú)負荷起動,在停車(che)前應停止加料,待(dài)機殼内📧輸送完物(wu)料後,方能停止運(yùn)轉。

l The error of portrait linearity and horizontal of body and bracket is the 1/1000 of length when install screw engine. Install the support on the body steadily and then lock down the ground bolt.

l Install the inlet and outlet on the spot. Add sealing shim between the two flanges and there is no clearance.

l The operation should be steady and reliable. There is no oil leakage in the bearing box and the raising temperature is not more than 20℃.

l Feed the material equally, otherwise the material will be jammed and the driving device is over loaded. There is no big block hard material in the transported material to avoid blocking and damaging.

l Often check the working condition of all parts during the operating. Pay attention to the working of transmission parts and add lubricant to the transmission parts.