工作(zuo)原理:

Working principle:

橡(xiang)膠、金屬(shu)聯接器(qi),主要由(you)松套法(fa)蘭,橡膠(jiao)、金屬波(bo)紋⚽管等(deng)🔞部件🤟組(zu)成。管道(dao)系統因(yin)環境溫(wen)度或使(shi)用溫度(du)産生冷(leng)縮或膨(peng)🚶♀️脹時,所(suo)産生的(de)力和變(bian)形量、偏(pian)移角🌍度(du),聯接👌器(qi)都能很(hen)好的補(bu)償。能吸(xi)收系統(tong)振動,降(jiang)低系統(tong)噪音,接(jie)頭兩端(duan)任意偏(pian)轉,能自(zi)由調節(jie)軸向或(huo)橫向位(wei)移等。

The rubber, metal connector is mainly made up of free flange, rubber and metal ripple pipe etc. The system pipe contracts or expands because of environment temperature or using temperature. The connector can compensate the force, distortion amount and excursion angle, which is made by contracting or expanding. It can absorb system quiver and reduce system noise. The joint ends can be deflected arbitrarily and adjust shaft freely.

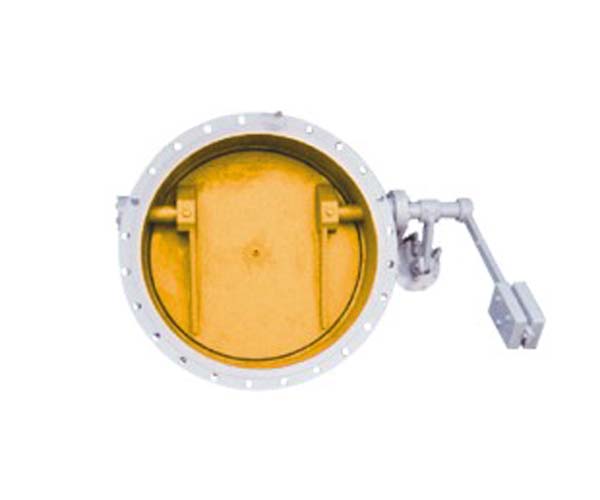

止(zhi)回閥,主(zhu)要由閥(fa)體、蝶闆(pan)、彈簧、絞(jiao)軸及橡(xiang)膠圈等(deng)部件組(zu)成🏃🏻。介質(zhi)由蝶闆(pan)無簧面(mian)進入,當(dang)兩半圓(yuan)形蝶闆(pan)在受介(jie)質壓力(li)♍超過彈(dan)簧支承(cheng)力後,使(shi)蝶闆自(zi)行打開(kai),當切斷(duan)前方☀️介(jie)質壓力(li)後,蝶闆(pan)在彈🌏簧(huang)壓力及(ji)介質反(fan)壓力作(zuo)用下迅(xun)速關閉(bi)。微🏃♀️阻緩(huan)閉止🧑🏽🤝🧑🏻回(hui)閥,蝶闆(pan)🚩在彈簧(huang)壓力⭕及(ji)介質反(fan)作用力(li)下觸及(ji)液壓微(wei)阻裝置(zhi),随着反(fan)作用力(li)增大,蝶(die)闆緩緩(huan)關閉。風(feng)道止回(hui)閥,蝶闆(pan)在重🈚錘(chui)作用💚力(li)及介🛀🏻質(zhi)反作用(yong)力下迅(xun)速關閥(fa)。

The check valve is mainly made up of valve body, butterfly board, spring, wring shaft and rubber ring etc. the medium enter from butterfly board which is without spring. When medium pressure of the two round butterfly boards is beyond the spring bearing, the board will open itself. When cut off the medium pressure ahead, the board will close quickly on the effect of spring pressure and medium counterforce. The board of micro-block slow-close check valve touches the hydraulic micro-block device on the effect of spring pressure and medium anti-pressure. The board closes slowly as the counterforce increasing. The board of venting pipe check valve close quickly on the effect of hammer force and medium counterforce.

安裝及(ji)調試:

Installation and regulation

l 安(an)裝前必(bi)需清潔(jie)閥門内(nei)腔,不允(yun)許有任(ren)何雜物(wu)和污垢(gou)🏃附着。

l 法(fa)蘭式連(lian)接在安(an)裝時,兩(liang)法蘭間(jian)需加密(mi)封墊。對(dui)夾式連(lian)接在安(an)裝時,在(zai)法蘭與(yu)閥體連(lian)接處需(xu)加密封(feng)墊,然後(hou)均勻擰(ning)緊螺💘栓(shuan)。

l 止回閥(fa)安裝時(shi)請注意(yi)流向(閥(fa)體上有(you)箭頭标(biao)明)。

l 安裝(zhuang)時請調(diao)整使伸(shen)縮管伸(shen)出到伸(shen)縮量的(de)1/2。使用一(yi)定🌈期限(xian)後,需更(geng)換密封(feng)圈。

l The body must be cleaned before installed and there is no dirt and sundries clinging to the body.

l Add seal cushion between two flanges of flange type connection or between the flange and valve body of dual clamp type connection, then screw down bolt when installs the valve.

l Pay attention to the flow direction of check valve when install. There is arrow on the valve body.

l Extend the pipe to the 1/2 of extension amount when install the extension pipe. Seal rings need to be exchanged after the steel extension pipe has been used for a period of time limit.

訂貨(huo)須知:

Information for order

l 選(xuan)用訂貨(huo)時,請參(can)照産品(pin)樣本注(zhu)明産品(pin)規格、型(xing)号及技(ji)術參數(shu)(使用溫(wen)度,設備(bei)工況、介(jie)質性質(zhi)及工作(zuo)壓力等(deng))。

l 表格中(zhong)未列的(de)規格、用(yong)于特殊(shu)介質或(huo)其它特(te)殊要求(qiu),請與我(wo)公司銷(xiao)售部、技(ji)術部聯(lian)系,可為(wei)您另行(hang)設計制(zhi)造。

l Please indicate the type, model and technical parameter (using temperature, working condition of equipment and characteristic of medium etc) referring to the product sample when you place an order

l If you have other special demand, need special medium or the spec that is not listed in the table, please contact with our department of market and technology. We can design and manufacture for you especially.